Slotted & Plain

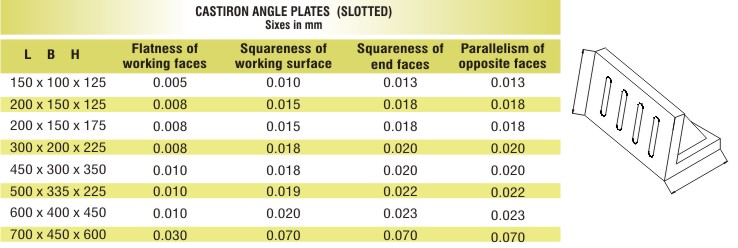

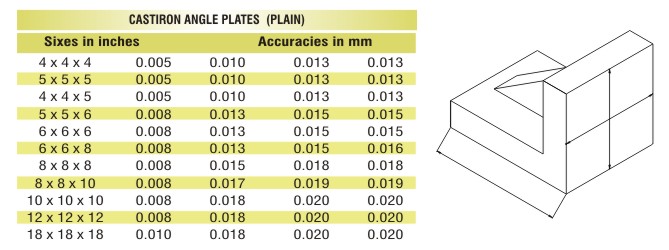

| Cast Iron Angle Plates ( Slotted ) IS 2554-1971 • Angle Plates are made of high duty close grained cast iron to IS : 210 Grade 20. They are wel ribbed to minimise distortion and artificially seasoned as recommended in IS : 2554 - 1971. • Cast iron Angle Plates confirm to IS : 2554 - 1971 and are offered in two grades. Grade I & Grade II.They are manufactured in different sizes to meet a wide range of requirements. • Grade I Plates are very carefully handscraped on all working surfaces to accuracies confirming to Grade 1 limits as per IS : 2554 - 1971. • Grade II Plates are finish machined on all working surfaces to accuracies confirming to Grade II limits as per IS :2554 - 1971. |

• Angle Plates are made of high duty close grained cast iron to IS : 210 Grade 20. They are wel ribbed to minimise distortion and artificially seasoned as recommended in IS : 2554 - 1971.

• Cast iron Angle Plates confirm to IS : 2554 - 1971 and are offered in two grades. Grade I & Grade II.They are manufactured in different sizes to meet a wide range of requirements.

• Grade I Plates are very carefully handscraped on all working surfaces to accuracies confirming to Grade 1 limits as per IS : 2554 - 1971.

• Grade II Plates are finish machined on all working surfaces to accuracies confirming to Grade II limits as per IS :2554 - 1971.

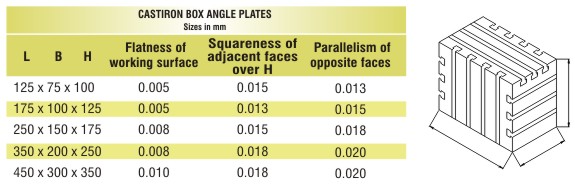

• Cast Iron Box Angle Plates are made of high duty close grained cast iron to IS : 210 Grade 20. They are artificially seasoned as recommended in IS : 6232 - 1971.

• Cast iron Box Angle Plates confirm to IS : 6232 - 197 1 and are offered in two grades, Grade I & Grade II.They are manufactured in different sizes to meet a wide range of requirements.

Used for Grinding, Light Milling, Drilling & Inspection of Round & Square Jobs.

Accuracy for Flatness, Squareness and Parallelism within 0.005mm upto 6”L & 0.010mm for 8” L of

"V"block

The Bigger V angle &bottom holding surface are equipped with hardened strips for wear resistance. Uniform and strong magnetic pull to all three magnetic surfaces Top, Bottom & V face.

Hardness of V face is 60±2 Rc.

Powder Coated.

Easy ON- OFF facility.

120o " V " angle also available.

Sr.No.

Cat No.

Size

Range (mm)

Pull

1. UL-10101 Soft

40L X 40W X 50H [2"]

Ø 3 - Ø 25

25 Kg

2. UL-10101 Hard 40L X 40W X 50H [2"] Ø 3 - Ø 25 25 Kg

3. UL-10102 Soft 75L X 56W X 75H [3"] Ø 5 - Ø 40 75 Kg

4. UL-10102 Hard 75L X 56W X 75H [3"] Ø 5 - Ø 40 75 Kg

5. UL-10103 Soft 100L X 70W X 95H [4"] Ø 5 - Ø 65 100 Kg

6. UL-10103 Hard 100L X 70W X 95H [4"] Ø 5 - Ø 65 125 Kg

7. UL-10104 Soft 150L X 75W X 100H [6"] Ø 5 - Ø 70 125 Kg

8. UL-10104 Hard 150L X 75W X 100H [6"] Ø 5 - Ø 70 150 Kg

9. UL-10105 Soft 200L X 125W X I50H [8"] Ø 10 - Ø 140 175 Kg

10. UL-10105 Hard 200L X 125W X I50H [8"] Ø 10 - Ø 140 175 Kg

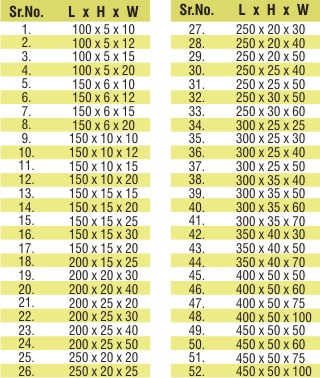

Parallel Blocks

;Hardened and ground to 55 to 60 HRC.

;Ground & finished on four sides.

;Precision ground in matched pairs.

;Variation in ranched parallels is within 0.010 mm.

;Thickness, width & length are nominal & within +

;0.1 mm upto 200 mm length & + 0.2 mm upto

;450 mm length.

;Accuracy for parallelism & squareness is + 0.005

;mm upto 200 mm length and + 0.010 mm upto

;450 nun length.

;All the four sides are chamfered.

;Supplied in Grade A & Grade B as per IS : 4241

;1967.